| IN A NUTSHELL |

|

The world of electronics is on the brink of a revolutionary transformation thanks to the development of a new type of electronic ink. This cutting-edge technology could fundamentally change how we interact with electronic devices, paving the way for a future where gadgets can switch between rigid and soft states with ease. Imagine medical implants that become more comfortable inside the body or flexible robotics that can adapt to their surroundings. This innovation, driven by the unique properties of gallium, is poised to make these visions a reality.

How Gallium and Polymer Work Together

At the heart of this innovation is gallium, a metal known for its unique ability to transition between solid and liquid states around body temperature. Combined with a polymer-based solvent, this material is transformed into a printable ink that becomes conductive when heated. The solvent, dimethyl sulfoxide (DMSO), plays a crucial role by breaking down under heat, creating an acidic environment that strips away the protective oxide layer on gallium particles. This reaction allows the particles to merge and form conductive pathways, enabling the seamless transition between hard and soft states.

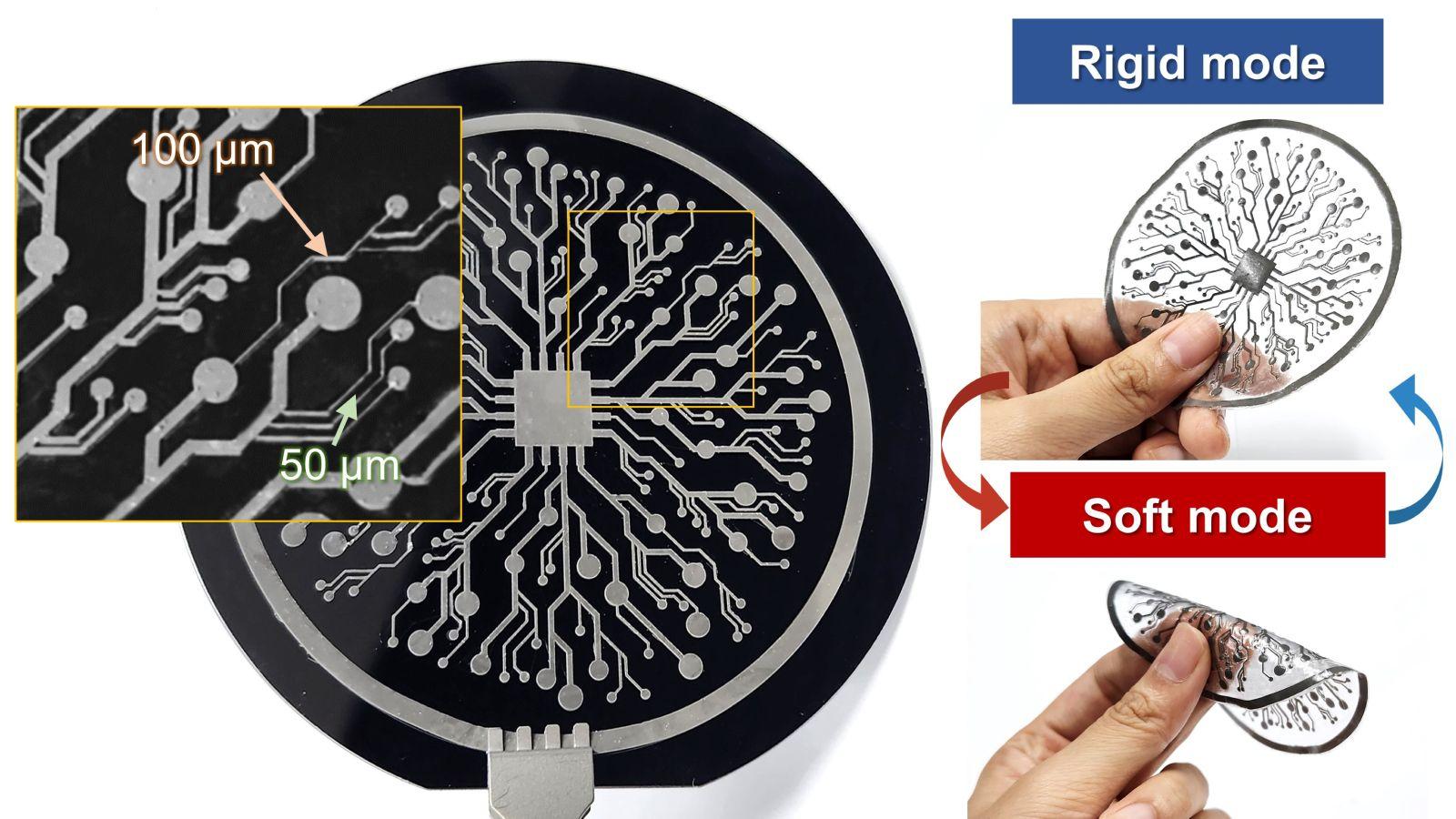

By dispersing microscopic gallium particles into a polymer matrix, scientists have created a flexible, ink-like base. This groundbreaking method allows for the printing of features as small as 0.002 inches, demonstrating the precision achievable with this technology. Such advancements make it possible to create devices that can alter their stiffness as needed, offering a blend of durability and flexibility previously thought unattainable.

Potential Applications in Medical and Robotics Fields

The implications of this technology are vast, especially in the medical and robotics fields. For instance, researchers have already developed a wearable health device that remains rigid at room temperature but softens upon contact with skin, enhancing comfort without sacrificing functionality. Additionally, a flexible brain implant was created that stays rigid during surgery for precise insertion, then softens once inside the brain to minimize irritation and inflammation.

In the realm of robotics, this ink could lead to the development of machines capable of performing tasks in environments where adaptability is crucial. Imagine robots that can transform to navigate tight spaces or alter their form to interact more effectively with their surroundings. The potential for these devices extends into various industries, including healthcare, manufacturing, and beyond.

Overcoming Challenges in Liquid Metal Printing

One of the most significant achievements in this research is overcoming the longstanding challenges associated with liquid metal printing. Gallium, despite its promising properties, has been difficult to use in printed electronics due to its high surface tension and tendency to oxidize. This oxidation forms a crust that hinders bonding and spreading, presenting a significant barrier to practical application.

The innovative process developed by the researchers at the Korea Advanced Institute of Science and Technology (KAIST) cleverly addresses these issues. By controlling the ink’s acidity, they achieved both electrical and mechanical connections in printed gallium particles, facilitating the room-temperature fabrication of high-resolution, large-area circuits. This breakthrough not only enhances the practicality of using gallium in electronics but also opens up possibilities for large-scale, 3D-printed electronics in the future.

Future Prospects and Industry Impact

The introduction of variable-stiffness electronics could significantly impact the electronics industry. By bridging the gap between rigid and flexible devices, this technology enables a new level of versatility in design and application. Common manufacturing techniques such as screen printing and dip coating can be used with this ink, suggesting that scaling up production for commercial use is feasible.

The potential for this technology to reshape how we use and interact with electronics is immense. From personal devices that adapt to user needs to industrial applications that enhance efficiency and performance, the scope for innovation is vast. As researchers continue to refine and develop this technology, we may soon see a wave of new devices that redefine the boundaries of what electronics can do.

As this technology advances, it invites us to consider the broader implications of such adaptable devices. How will the ability to shift between states impact the design and functionality of future electronics? Could this lead to innovations that we can’t yet imagine, transforming industries and everyday life in profound ways?

Did you like it? 4.6/5 (29)

Could this be the future of wearable tech? 🤔

Wow, I can’t wait to see this in action! 🥳

I’m a bit skeptical about the durability of such devices. Has this been tested thoroughly?

Thank you for sharing such fascinating insights into the future of electronics!

How long until we can buy products using this technology? 😊