| IN A NUTSHELL |

|

In the world of advanced materials, the development of ultra-high temperature ceramics (UHTCs) marks a significant milestone. Capable of withstanding temperatures exceeding 3,632 degrees Fahrenheit, these remarkable materials are indispensable in critical applications such as nuclear reactors, spacecraft heat shields, and hypersonic vehicles. Traditionally, the manufacturing process for these ceramics has been both time-consuming and energy-intensive, relying on massive furnaces. However, a breakthrough method using laser sintering has emerged, promising to revolutionize the production of these materials. This article delves into the innovative laser sintering technique and its implications for the future of material science.

The Power of Laser Sintering

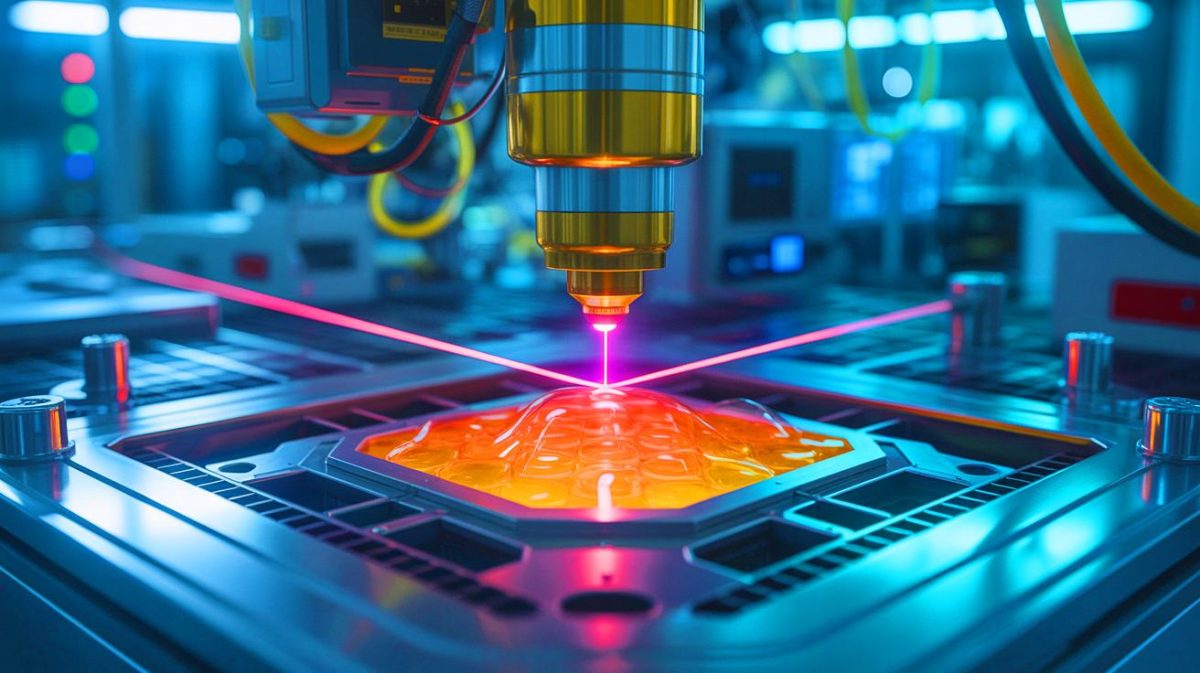

The innovative method, developed by researchers at North Carolina State University, utilizes a 120-watt laser to produce UHTCs in a matter of minutes. This process, known as laser sintering, involves converting a liquid polymer precursor directly into hafnium carbide (HfC), one of the most heat-resistant materials available. The method begins in an inert environment, typically a vacuum chamber filled with argon gas. Here, the laser is applied to the liquid polymer precursor, which contains the necessary chemical components to form the final ceramic: hafnium and carbon.

When the laser hits the precursor, the thermal energy converts the liquid polymer into a solid, which then transforms into ceramic. Remarkably, this entire sintering process occurs so rapidly that it is considered a single-step procedure. By speeding up the production process, laser sintering offers an efficient alternative to traditional techniques, potentially transforming industries reliant on these high-performance materials.

Versatility in Application

One of the key advantages of the laser sintering method is its versatility. The process can be employed in two distinct ways to engineer UHTCs. Firstly, the liquid precursor can be applied as a coating to existing structures, allowing for the creation of protective ceramic layers without subjecting the entire structure to the intense heat of a furnace. This method is particularly beneficial for materials sensitive to high temperatures, preserving their integrity while enhancing their durability.

Alternatively, the laser sintering technique can be integrated with 3D printing systems, akin to stereolithography. In this approach, the laser is mounted on a movable platform placed over a vat containing the liquid precursor. By tracing the design layer by layer, the laser gradually constructs a 3D ceramic object with precision and control. This integration of laser sintering with 3D printing opens up new possibilities for custom-designed UHTCs, catering to specific requirements in various industries.

Efficiency and Yield

The researchers’ proof-of-concept experiments demonstrated the high efficiency of their laser sintering method. They successfully produced pure HfC, achieving a higher yield compared to conventional techniques. The laser sintering process converted at least 50% of the precursor mass into ceramic, a significant improvement over the 20-40% yield typical of traditional methods. Such efficiency results in reduced waste and improved resource utilization, making the technique both economically and environmentally advantageous.

Moreover, the laser sintering method exhibited excellent bonding of HfC coatings on carbon-fiber reinforced carbon composites. These coatings uniformly covered the surface and bonded tightly to the underlying structure. This achievement marks the first known instance of producing high-quality HfC from a liquid polymer precursor, as highlighted by Prof. Cheryl Xu, co-author of the research paper published in the Journal of the American Ceramic Society.

Future Implications

The portability of the laser sintering method, despite the requirement for a vacuum chamber, presents numerous opportunities for industrial applications. Unlike traditional furnace-based techniques, this method can be implemented in more flexible environments, potentially accelerating the adoption of UHTCs across various sectors. As industries continue to push the boundaries of performance and durability, the ability to quickly and efficiently produce high-quality ceramics becomes increasingly vital.

The implications of this breakthrough extend beyond material science, influencing fields such as aerospace, defense, and energy. By providing a scalable and efficient solution for manufacturing UHTCs, laser sintering could drive innovation and facilitate the development of next-generation technologies. As researchers further refine this technique, what new possibilities and applications might emerge in the realm of ultra-high temperature ceramics?

Did you like it? 4.4/5 (26)

Wow, 3,632°F without cracking? That’s hotter than my love life! 😜

How soon can we expect to see these materials in commercial applications?